MCC Services

Multi-Craft Contractors partners with clients to take on the most complex challenges. We pioneer innovative solutions to improve project performance and minimize downtime.

MCC Capability Statement

Flexible Turnkey Solutions from a Trusted Source

Mechanical

Mechanical

Electrical

Electrical

Plumbing

Plumbing

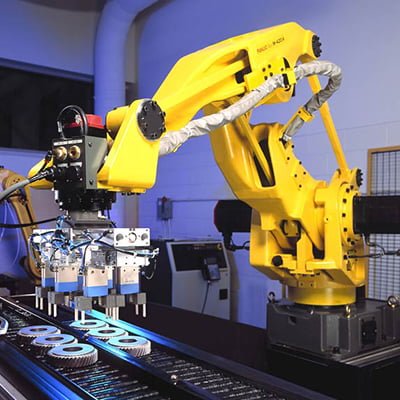

Automation

Automation

Crane & Rigging

Crane & Rigging

Fabrication

Fabrication

24/7 Service

24/7 Service